|

Ningbo J&D Autoparts Co., Ltd.

|

Insert Ball Bearing UC 206-18

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Premium OE quality ball bearings with 100% inspection

ISO Certified

Experienced & Direct OE supplied for many famous Automotive parts factory

Specifications:

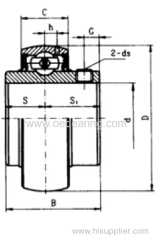

| Bearing NO. | Shaft Dia. | Dimensions(mm) / (in.) | Basic load rating(KN) | Mass | ||||||||

| d(in.) | D | B | C | S | S1 | G | h | ds | Dynamic Cr | Static Cor | (kg) | |

| UC 206-18 | 1-1/8 | 62 | 38.1 | 19 | 15.9 | 22.2 | 5.5 | 5 | M6 x 1 | 15 | 11.2 | 0.34 |

| 2.4409 | 1.5000 | 0.7480 | 0.6260 | 0.8740 | 0.2165 | 0.1969 | 1/4 -28UNF | |||||

Quality by Science

We employ statistical methods to our processes in order to assure our customers that we will deliver consistent quality. We monitor our key bearing characteristics by Statistical Process Control and achieve Cpk levels above the standard.

Predictability

It is more than luck that our quality record is flawless. Using mathematical distribution and probabilities, our performance can be predicted and is done as a regular part of our PPAP (Production Part Approval Process).

Material

JDA premium bearings are made from the highest quality materials. We use steel from the best steel sources available in the world. The high carbon bearing steel is vacuum degassed SAE 52100 or GCr15. Vacuum degassing yields stronger steel with less impurities.

State of The Art Grinding

Our CNC grinding equipment holds high precision tolerances and accuracy that is required to produce the highest quality level ABEC rated bearings.

Automated Assembly Lines

Our factory employs automated assembly lines that perform matching, assembly, test, lubrication, and capping without human error.

Centralized Filtration System

Our grinding fluids are filtered through a European style centralized filtration system. The cleanliness of the grinding fluids is instrumental toward providing better surface finish and smooth operation.

Precision Technology × 200

Accuracy, roundness, and consistency are checked by technologically advanced metrology equipment in our factory laboratory. Secondary checks are subsequently performed at our headquarters by independent certified laboratories.

Mathematical / Scientific Analysis

Our processes are guided by SPC methodologies which give us a predictive advantage on our long term quality and consistency. We can also employ scientific methods such as Weibull Failure Analysis to analyze cause and effect. Our engineering staff can also design specialty raceways to significantly increase calculated bearing load capacity.

Profesional Details

While product, quality, engineering, and service are all key elements – JDA knows that there are many smaller details that are also critical. Items like packaging, barcode labels, PPAP, shipping releases, ASN's, change anagement, schedules, and IMDS are subsequent critical elements. JDA handles all of the details with professionalism that is demanded in the OEM industry.